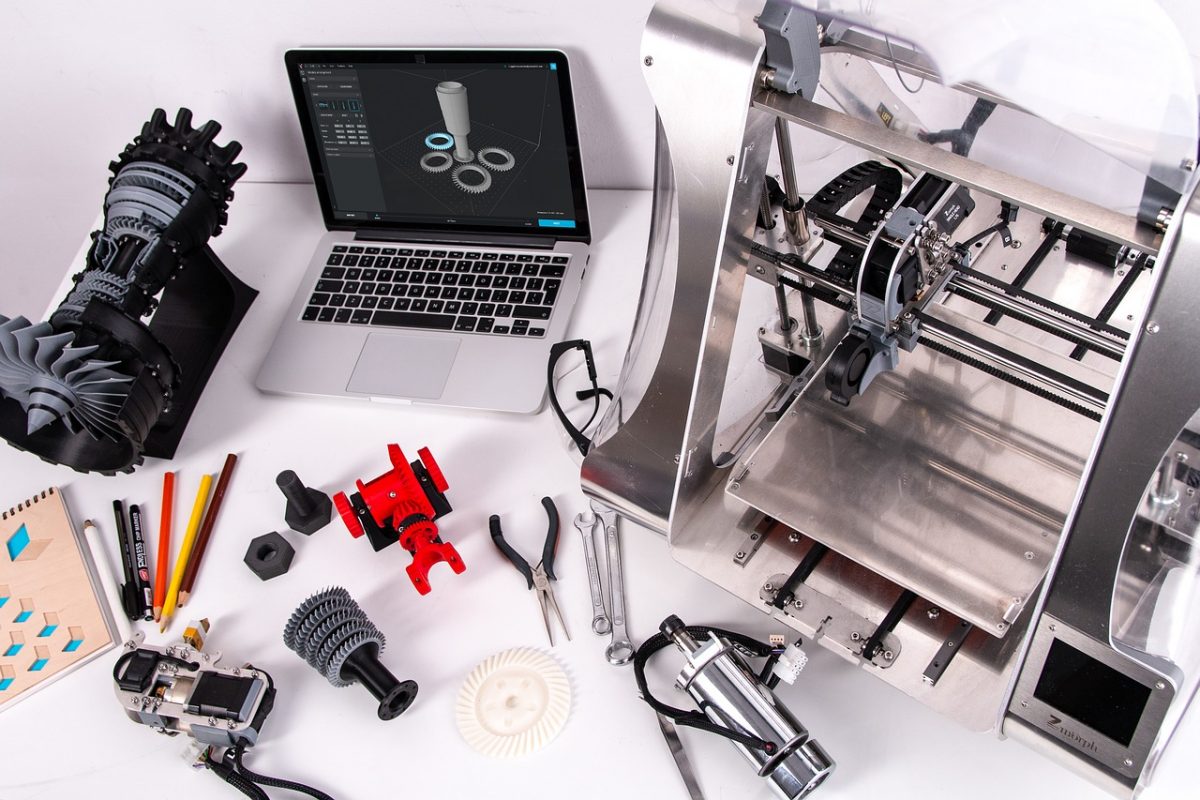

The additive manufacturing or widely known as 3D printing can make a digital computer-aided design (CAD) into physical products. They do this by using a layer-upon-layer method of Printing to form input substrate materials.

There is still a lot of improvement to be done before 3D printing will become an everyday technology, but we are closer than ever. For example, NASA implemented the technology to rapidly create sustainable housing solutions for Earth and Mars. They launched a $3.5 million 3D-printed habitat challenge competition, with emphasis on the fast and effective deployment of housing in spiteful conditions. Additionally, it will allow for more sustainable exploration missions by the help of robotic construction techniques using 3D printing.

Not just that, there's more, here are ways 3D printing will change the world:

Democratization of Production

3D printing will break the manufacturing value chain by:

- Giving end-users the ability to finish custom designs at short notice.

- Shortening the production cycle by reducing the lead time between design, prototyping, and mass production to a few days.

- It reduces negative customer feedback as well as waste incurred at production.

- 3D printing removes complications from manufacturing; no matter how complicated your plan, you don’t need complicated tools to bring your design to life; the printer breaks down your complexity by layer while reducing the cost of production. This is better compared to traditional methods.

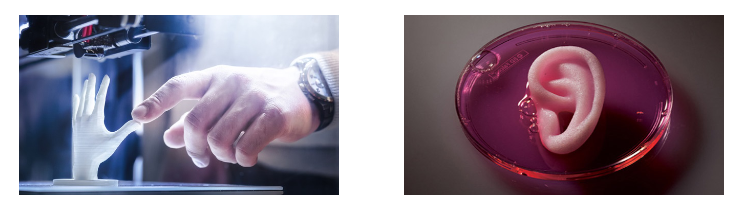

Bioprinting

An offshoot of traditional layer-by-layer 3D Printing with biomaterials (human cells) called Bioprinting which focuses on producing living tissue, blood vessels, and organs for biomedical use.

Bioprinting is evolving slowly compared to mainstream 3D Printing because the human body is very complicated to understand. The human brain is the most complex object in the universe because it has over 100 billion neurons, .

Though there is still a long way ahead, Bioprinting is very exciting because it enables personalized treatments with the printing of individual and targeted tissues. We can print you a new one if your kidney, liver, or heart fails. Personalized prosthetics currently demonstrate the power of coordination between medicine and 3D printing. Welcome to the future of medicine!

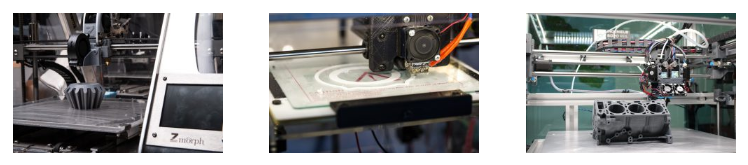

3D Metal Printing

The crown jewel of 3D printing technology is the Direct Metal Printing (DMP); it is an additive manufacturing process that builds high-quality complicated metal parts from 3D CAD data. It enables the creation of machine parts previously thought impossible due to complex shapes.

DMP is critical in industries because:

- It allows for the production of complicated and minute machine parts without contracting any extra cost on tooling

- Fast design and prototyping at the tightest tolerance

- By reducing the gap between aesthetics and functionality it optimizes design and manufacture. Removing complexities from designs creates room for better models with faster load and better strength spread.

- It increases the number of metal alloys that can be 3D printed.

The 3D-printing industry has only one way and that is to go—up. At its peak, 3D printing will break traditional manufacturing by improving productivity and by reducing the lead time between thoughts and products.